Master Cell Banks: Laying the Foundation to Final Product Success

Consider our top 5 FAQs when it comes to MCBs

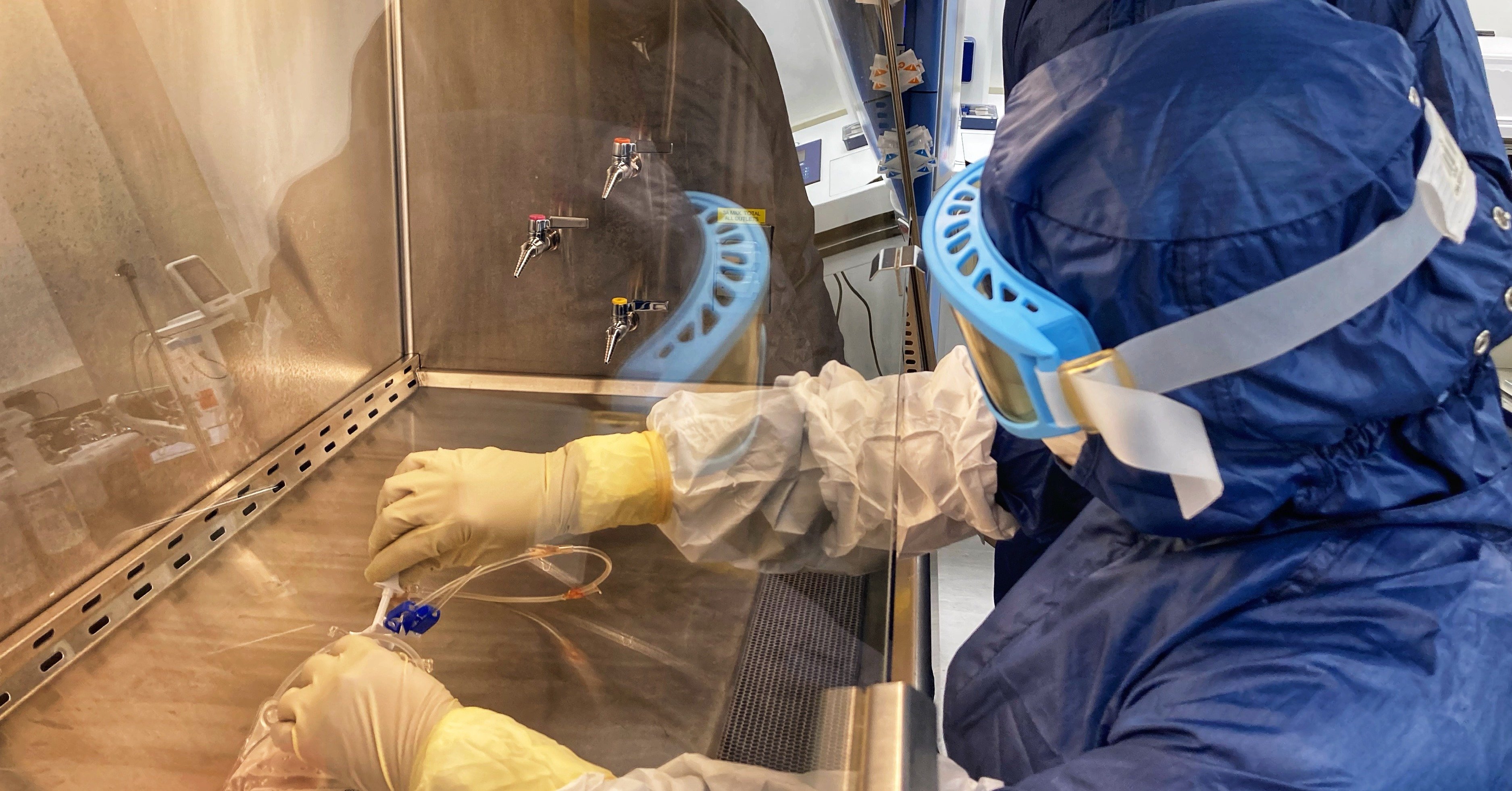

Master cell banks (MCBs) are a critical starting material that lay the foundation for the scale-up and production of cell and gene therapies, biologics, and vaccines. MCBs play a key role in ensuring product consistency and managing risk by eliminating contamination, degradation, extraneous agents, and genetic instability. By investing in the establishment and maintenance of a high-quality MCB, therapeutic developers can set themselves up for long-term success and ensure supply chain sustainability.

MCB integrity requires strict adherence to good manufacturing practices (GMPs) and quality control measures. Therapeutic developers who are on the path to manufacturing a clinical-grade product drug will often rely on the expertise and experience of a manufacturing partner for the MCB. Regular testing and characterization of the cells in the MCB is necessary to ensure their identity, purity, and to detect any changes that could impact the quality of the final product. These rigorous requirements can be a daunting task for developers who may lack the expertise, resources, or capacity. By leveraging a partner who will generate, monitor, and perform release and characterization testing of an MCB, developers can be confident that the cells remain stable and consistent over time, which is essential for ensuring the quality and safety of the final product.

Our Top 5 MCB FAQs:

1. What should I consider when choosing a partner to manufacture an MCB?

Since the quality of the MCB is critical to your end product’s success, consider these four questions when choosing a manufacturing partner:

- a. How much experience does the manufacturing partner have and have they produced a master cell bank with your desired cell type?

- b. What quality and regulatory systems does this provider have in place to ensure the quality and safety of the final product?

- c. Does the provider have capacity to produce the required number of vials to meet my timelines?

- d. Does the manufacturing partner offer other manufacturing services that enable end-to-end processing under one roof?

2. What type of testing should be done on my MCB?

At a minimum, the following tests should be performed on an MCB:

- Identity testing

- Purity testing

- Viability testing

- Genetic stability testing

- Sterility testing

- Mycoplasma testing

- Endotoxin testing

- Extraneous Agents

3. What other services are available at Resilience's MCB facilities?

MCB generation happens at 3 facilities across the Resilience network:

Alachua, FL, Research Triangle Park (RTP), NC and Marlborough, MA

In addition to MCB services, these facilities can manufacture both drug substance (DS) and drug product (DP).

4. What cell types has Resilience worked with for MCBs?

The Resilience team has extensive experience working with:

- HEK293, adherent and suspension

- E. coli

- Vero

- HeLa

- CHO

5. Does Resilience have capacity to start manufacturing my MCB today?

Yes! With 3 sites located across North America, we have capacity to begin manufacturing your MCB today. Resilience offers competitive pricing and 50% of the cost of an MCB can be credited towards a future GMP manufacturing campaign for drug substance and drug product (terms and conditions apply, inquire within). With timelines of less than 6 months for release, set up your best tomorrow by working with Resilience today.

Have more questions? Connect with our team today to get started